How to make Sri Lanka’s anagi II stove

Practical Action

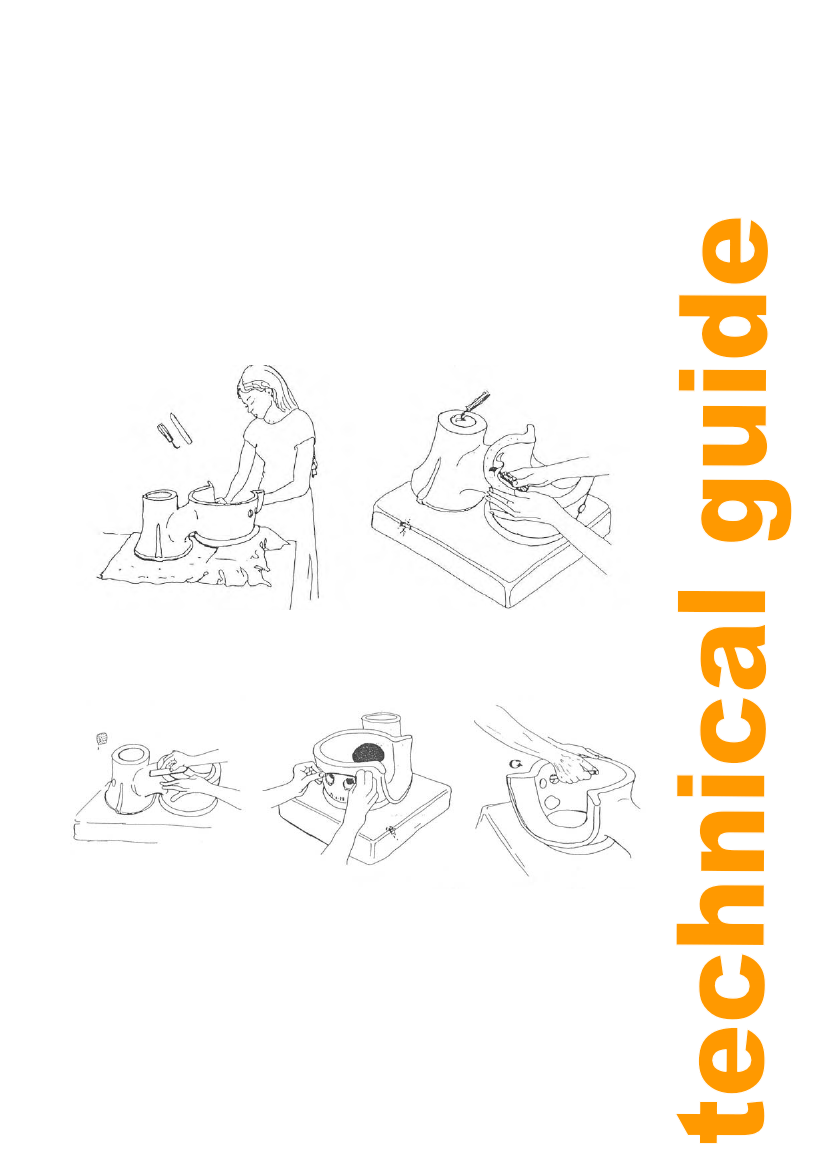

Finishing Procedure

After 3 days of stiffening indoors on the pallet, the stove can be removed from the pallet

without distortion. At this time the final finishing is done to the stove. Sharp edges are

carved away and those areas are dampened with a sponge. They are then rubbed with a

wooden stick. The stick is then used to rub joints, especially the tunnel, baffle, and door

joints. It is necessary to turn the stove upside down for most of this procedure. Either use a

3” thick stiff foam rubber pad, or support the shorter firebox with a cloth covered brick. The

whole procedure should require only 10 minutes.

In some factories, the assemblers "finish" the stoves they assembled. In other factories, the

finishing work is all done by one person.

Note: Configuration of brick with cloth covering as support for the stove while it is upside

down. All other illustrations show the foam pad.

1. Here she is carving away any sharp edges

around the door. She then rubs the areas

with a stick.

2. The sharp edges on the bottom of the fire

box and the second pothole are carved away.

3. They are dampened with a

sponge, and then rubbed with A

wooden stick.

4. The sharp edges on the

airholes are carved off with

the knife.

5. They are then dampened and

rubbed with a stick.

27